1. Efficient Transport of Liquids and Gases

In the chemical and oil industries, the efficient transportation of liquids and gases is a fundamental function of industrial pumps. Whether it is the transportation of raw materials or the pipeline delivery of finished products, pumps play an indispensable role in these processes. Specifically, industrial pumps are used for:

a) Raw Material Transport

In the oil industry, industrial pumps are used to extract crude oil from the oil fields and transport it to refineries or storage facilities. The pump is responsible for lifting the crude oil from the underground reservoir to the surface and moving it through pipelines.

b) Fluid Handling

In the chemical industry, pumps are commonly used to handle chemical solvents, catalysts, and other essential liquids. Different chemicals have different physical properties (e.g., viscosity, corrosiveness), so pumps must be designed to account for these fluid characteristics to ensure stable operation.

c) Gas Transport

In the oil and gas industry, pumps are also used for gas transportation. For instance, natural gas is transported via high-pressure pipelines, and pumps help ensure the stable flow of gas through these systems.

2. Precise Control of Fluids

In the production processes of the chemical and oil industries, many reactions require fluids to enter reactors at specific speeds, pressures, and temperatures. This is where the precise control provided by pumps becomes crucial.

a) Flow Control

In chemical reactions, the flow of fluids directly affects the efficiency of the reaction and the quality of the product. Modern industrial pumps can adjust the flow rate, pressure, and other parameters to ensure optimal reaction conditions.

b) Pressure and Temperature Control

Some reactions require maintaining specific pressure and temperature conditions. The pump’s ability to control pressure and temperature ensures that fluids enter the reactors in a stable state, avoiding excessive or insufficient pressure that could lead to accidents.

3. Handling Corrosive and High-Temperature Fluids

In the chemical and oil industries, many processes involve handling highly corrosive or high-temperature fluids. Pumps must be capable of operating under these extreme conditions.

a) Corrosive Fluid Handling

Many chemicals, such as acids, alkalis, and solvents, are highly corrosive, posing high demands on pump materials. Pumps are typically made from corrosion-resistant materials such as stainless steel, titanium alloys, or ceramics to withstand harsh chemical environments.

b) High-Temperature Fluid Handling

In petroleum refining, the temperatures of fluids can exceed 300°C. Pumps used to handle high-temperature fluids must be designed to withstand these elevated temperatures without suffering from material degradation or reduced performance.

4. Durability and Reliability

The production environments in the chemical and oil industries are often very harsh, requiring pumps to have high durability and reliability.

a) Continuous Operation

Oil extraction and chemical manufacturing often require 24-hour continuous operation, and any failure of equipment can lead to production downtime. Therefore, industrial pumps must be highly reliable and capable of withstanding extended periods of operation without failure.

b) Preventing Leaks and Contamination

In processes involving toxic, flammable, or corrosive fluids, the pump’s sealing ability is critical. Modern pumps use double mechanical seals and other technologies, such as seal liquid cooling, to prevent leakage and minimize environmental contamination.

5. Environmental Protection and Wastewater Treatment

In the oil and chemical industries, wastewater and emissions treatment is a key environmental concern. Industrial pumps play an essential role in these processes.

a) Wastewater Transport and Treatment

In chemical production, wastewater collection, transportation, and treatment require efficient pumping systems. Pumps ensure that wastewater flows effectively through treatment systems, reducing pollutant concentrations to meet discharge standards.

b) Oil-Water Separation and Discharge

In oil extraction, oil-water separation is a crucial step. Pumps are used in oil-water separation units to move the mixed oil and water to wastewater treatment systems for further processing.

6. Production Enhancement and Energy Savings

In the oil and chemical industries, energy efficiency is crucial, especially as energy costs rise. The efficiency of pumps directly impacts the economics of production.

a) Improving Production Efficiency

By optimizing the design and operating parameters of pumps, industrial pumps can reduce energy loss and improve the efficiency of fluid transportation. This not only helps improve productivity but also reduces energy consumption.

b) Application of Energy-Saving Technologies

With technological advances, modern industrial pumps employ energy-saving technologies, such as variable-frequency drives (VFDs) and low-noise designs, to adjust operating conditions based on the flow and pressure needs, avoiding unnecessary energy waste.

7. Automation and Intelligence

Modern industrial pumps are increasingly moving toward intelligent systems, optimizing operation through automation.

a) Automatic Monitoring and Adjustment

Intelligent pumps can monitor parameters such as flow rate, pressure, and temperature in real time. They automatically adjust to optimize work efficiency. For instance, the pump can adjust its flow rate automatically according to the needs of the chemical process, reducing the need for manual intervention.

b) Fault Diagnosis and Prediction

Modern pump systems are equipped with sensors and monitoring systems to detect any irregularities in pump performance. These systems predict potential failures, allowing for preventive maintenance and reducing the likelihood of unexpected downtime.

8. Handling Extreme Operating Conditions

In the oil and chemical industries, many operational environments are complex and hazardous, requiring pumps that can handle extreme conditions.

a) High-Pressure Environments

Certain oil extraction and chemical processes require operations under ultra-high pressure. Pumps must be capable of handling these pressures to ensure stable fluid transport without failure.

b) Extreme Temperature Conditions

In specialized applications, such as offshore oil extraction, pumps must operate in extremely low temperatures. Pumps must be designed to resist freezing and function reliably in these harsh conditions.

9. Diverse Pump Types for Different Needs

The chemical and oil industries require pumps to handle a wide variety of fluids, each with its own characteristics. Different pump types are suited for different tasks.

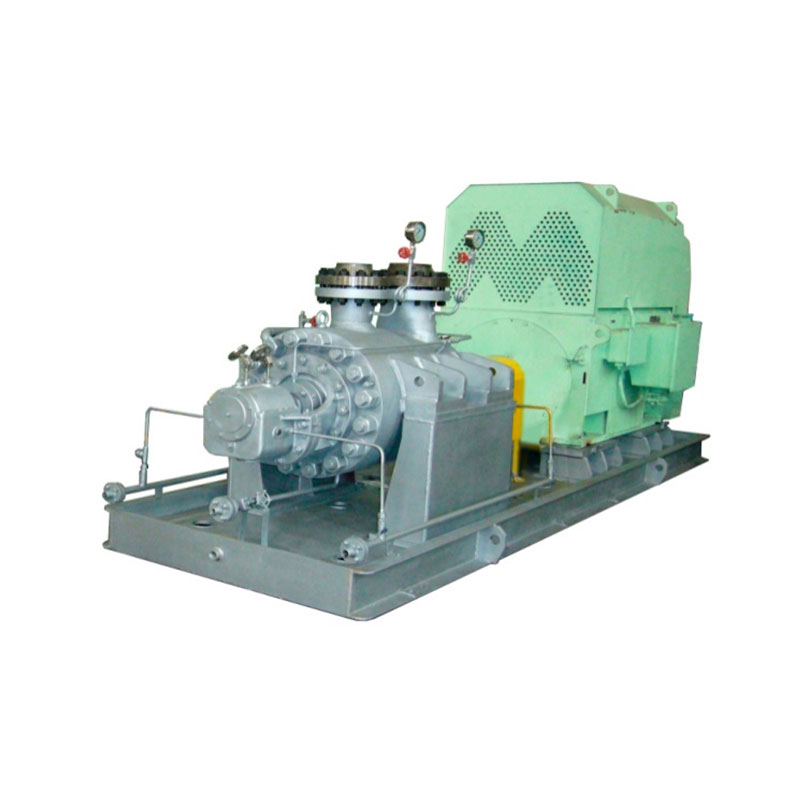

a) Centrifugal Pumps

Centrifugal pumps are widely used for transporting low-viscosity liquids such as water, solvents, and oils. They are suitable for high-flow applications in chemical plants.

b) Screw Pumps

Screw pumps are ideal for high-viscosity fluids, such as heavy oils and asphalt, which are commonly found in the oil industry.

c) Diaphragm Pumps

Diaphragm pumps are used for handling hazardous chemicals and slurries containing solid particles. These pumps are highly corrosion-resistant and are commonly used in processes involving acids and alkalis.

10. Emergency Backup and Redundant Design

In the oil and chemical industries, the redundancy of equipment is crucial, especially in critical production processes.

a) Redundant Pump Systems

To ensure that production continues uninterrupted in the event of equipment failure, many critical processes are equipped with backup pump systems. These redundant designs allow for seamless switching to backup pumps in the case of a failure in the primary pump.

b) Automatic Switching Functionality

Modern industrial pumps are equipped with control systems that can automatically switch between the main pump and the backup pump. This reduces the complexity of manual operations and minimizes the potential for errors.

| Pump Type | Applications | Features |

|---|---|---|

| Centrifugal Pump | Low-viscosity liquids (e.g., water, solvents) | High flow rates, simple structure, suitable for large-scale transport |

| Screw Pump | High-viscosity liquids (e.g., heavy oils, asphalt) | Suitable for high-viscosity fluids, strong adaptability |

| Diaphragm Pump | Hazardous chemicals, slurries containing solids | High corrosion resistance, used for handling specialty chemicals |

English

English русский

русский عربى

عربى

.jpg)

ENG

ENG

TOP

TOP