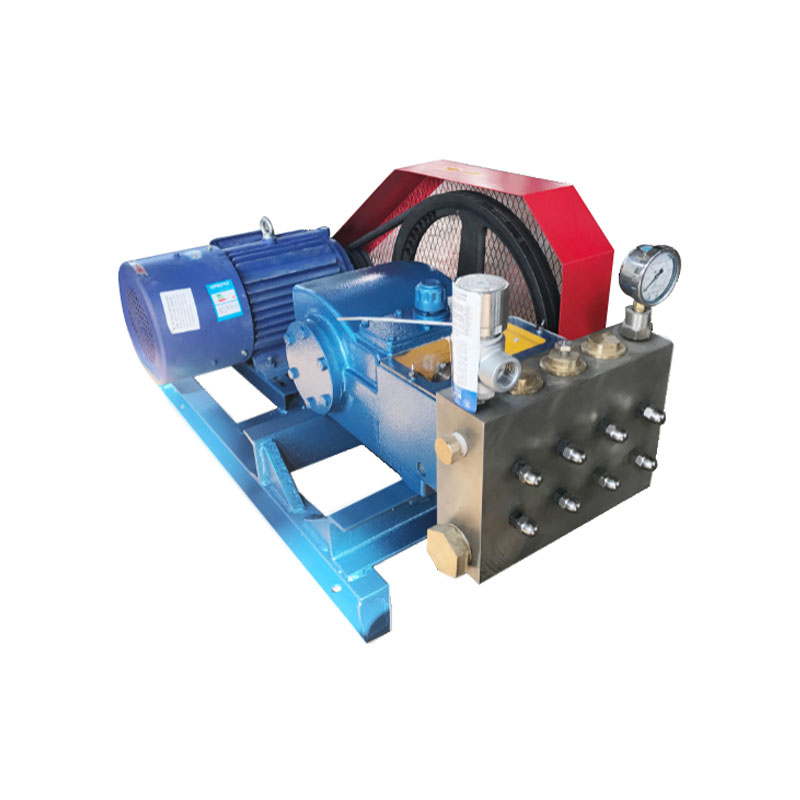

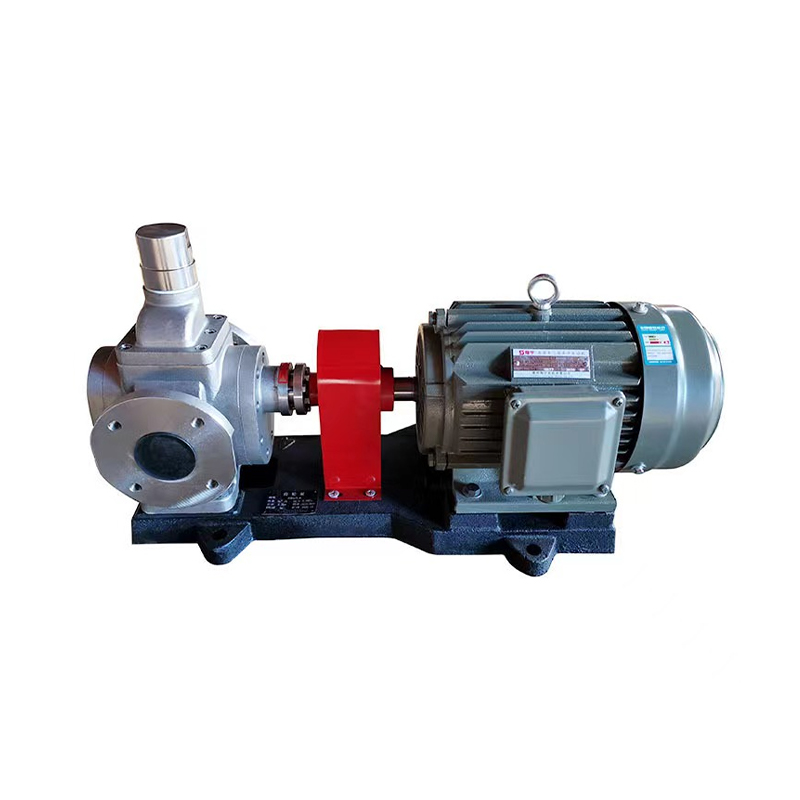

1. Introduction to Industrial Plunger Gear Pumps by Beloni

Industrial plunger gear pumps stand as a testament to engineering ingenuity, offering a robust and efficient solution for handling demanding fluid transfer applications. These pumps excel in conveying high-pressure, viscous, or abrasive fluids with precision and reliability, making them indispensable across various industries. Beloni (Jiangsu) Pump Manufacturing Co., Ltd., a distinguished name in the realm of industrial pump technology, has carved a niche for itself as a premier manufacturer and supplier of plunger gear pumps. With a steadfast commitment to quality, innovation, and customer satisfaction, Beloni has emerged as a trusted partner to industries worldwide. The cornerstone of Beloni's success lies in its deep-rooted understanding of customer needs and the ability to translate these requirements into cutting-edge pump solutions. By leveraging advanced design methodologies and state-of-the-art manufacturing processes, Beloni produces plunger gear pumps that consistently outperform industry standards. The hallmark of Beloni's industrial plunger gear pumps is their exceptional durability and longevity. Constructed from premium materials and engineered to withstand rigorous operating conditions, these pumps exhibit remarkable resistance to wear and corrosion. This ensures minimal downtime and reduced maintenance costs, contributing to overall operational efficiency. Beloni places a strong emphasis on energy efficiency in its pump designs. By optimizing pump components and hydraulic systems, the company has achieved significant reductions in energy consumption without compromising performance. This aligns with the global focus on sustainable practices and helps customers reduce their environmental footprint. Beyond product excellence, Beloni is dedicated to providing comprehensive support to its customers. The company offers a wide range of services, including expert consultation, installation, commissioning, and after-sales support. A team of highly skilled engineers and technicians is available to address customer inquiries and provide tailored solutions.

2. Maintenance of Industrial Plunger Gear Pumps

Proper maintenance is paramount in ensuring the optimal performance, longevity, and safety of industrial plunger gear pumps. A well-structured maintenance program not only prevents unexpected breakdowns but also maximizes the pump's efficiency and minimizes operational costs. Beloni (Jiangsu) Pump Manufacturing Co., Ltd. emphasizes the importance of regular maintenance and provides comprehensive support to its customers in this regard.

a)Preventive Maintenance: Regular inspections and routine maintenance tasks are crucial for maintaining the health of an industrial plunger gear pump. The following preventive maintenance practices are recommended: Lubrication: Adhering to the our recommended lubrication schedule is essential. Regular oil changes, using high-quality lubricants, and monitoring oil levels prevent premature wear and tear on internal components. Seal Inspection: Seals play a critical role in preventing leaks and maintaining pump efficiency. Regular inspection and replacement of worn seals are essential. Bearing Inspection: Bearings are subjected to significant loads and require periodic inspection and lubrication. Early detection of bearing issues can prevent catastrophic failures. Vibration Monitoring: Excessive vibration can indicate underlying problems. Regular vibration analysis helps identify potential issues before they escalate. Temperature Monitoring: Overheating can damage pump components. Monitoring pump temperatures and identifying the cause of overheating is crucial.

b)Corrective Maintenance: Despite preventive measures, issues may arise that require corrective action. Quick and effective repairs are essential to minimize downtime. Beloni offers comprehensive repair services to address various pump problems, including: Seal Replacement: Replacing leaking seals is often necessary to restore pump efficiency and prevent fluid loss. Bearing Replacement: Worn or damaged bearings must be replaced to avoid further damage to the pump. Pump Overhaul: For severe wear or damage, a complete pump overhaul may be required to restore performance. Component Replacement: Replacing worn or damaged components, such as gears or plungers, is essential for maintaining pump reliability.

c)Predictive Maintenance: To further optimize maintenance efforts, Beloni recommends implementing predictive maintenance strategies. This involves using advanced technologies to monitor pump condition and predict potential failures. By proactively addressing issues, downtime can be significantly reduced. Beloni recognizes the importance of operator training and provides comprehensive support to ensure proper pump operation and maintenance. Regular training sessions can enhance operator knowledge and promote best practices.

Well-executed maintenance program is essential for maximizing the lifespan and performance of industrial plunger gear pumps. By combining preventive, corrective, and predictive maintenance strategies, coupled with regular training and support, businesses can optimize their pump operations and minimize downtime. Beloni is committed to supporting its customers throughout the pump lifecycle, providing expert guidance and services to ensure the continued reliability and efficiency of their equipment.

English

English русский

русский عربى

عربى

ENG

ENG

TOP

TOP