1.Understanding the Applications of Industrial Screw Pumps

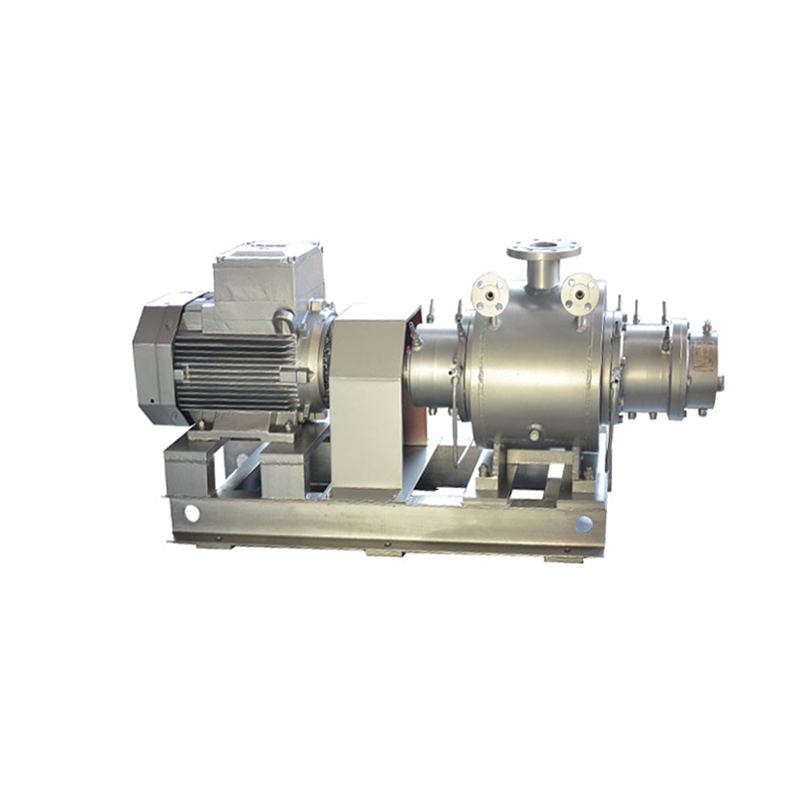

Industrial screw pumps are versatile and essential components in various industries due to their robust design and efficient performance. These pumps are commonly used in sectors such as petrochemical, coal mining, power generation, steel manufacturing, agriculture, municipal construction, and sewage treatment. Their ability to handle a wide range of fluids, including viscous and abrasive materials, makes them ideal for diverse applications.

In the petrochemical industry, screw pumps are employed for their reliable performance in transferring and handling crude oil, refined products, and chemical mixtures. Their design allows them to operate efficiently under high pressures and temperatures, which are typical in petrochemical processing. The precision and durability of screw pumps ensure minimal leakage and contamination, which is crucial for maintaining product quality and safety.

For coal mining operations, screw pumps are used to manage the extraction and transportation of slurry and other abrasive materials. The robust construction of these pumps enables them to withstand the harsh conditions found in mining environments. They are also utilized in dewatering applications, where they help remove excess water from mining sites, ensuring smooth and continuous operations.

In power plants, screw pumps play a critical role in various processes, including fuel handling, cooling water circulation, and sludge removal. Their ability to handle high flow rates and maintain efficiency under demanding conditions makes them suitable for applications such as circulating cooling water and transferring fuel to burners. This helps ensure the efficient and reliable operation of power generation systems.

Steel mills use screw pumps to manage the transfer of molten metal, slag, and other high-temperature materials. The pumps’ ability to operate at high temperatures and resist wear from abrasive materials makes them essential for maintaining the smooth flow of materials in steel production processes. Their reliability and performance are crucial for preventing disruptions and ensuring the quality of the final product.

In the agricultural sector, screw pumps are used for irrigation and drainage applications. Their ability to handle large volumes of water and maintain consistent flow rates is essential for effective irrigation systems. Additionally, these pumps are used in drainage systems to remove excess water from fields and prevent waterlogging, which is vital for crop health and productivity.

Municipal construction projects benefit from screw pumps in various applications, including water supply and drainage systems. The pumps are used to manage water distribution, remove stormwater, and handle wastewater in urban areas. Their efficiency and reliability help ensure the smooth operation of municipal infrastructure and contribute to the overall functionality of urban water management systems.

In the sewage treatment industry, screw pumps are employed to handle raw sewage, sludge, and other wastewater materials. Their ability to handle viscous and abrasive materials with minimal clogging makes them suitable for use in sewage treatment plants. By ensuring the effective transfer and processing of wastewater, screw pumps play a vital role in maintaining environmental hygiene and public health.

2.Advantages of Screw Pumps in Industrial Applications

One of the primary advantages of screw pumps is their high efficiency in transferring fluids. The helical screw design ensures a smooth and continuous flow, minimizing turbulence and energy loss. This efficiency is particularly important in applications where precise fluid handling is required, such as in the petrochemical and power generation industries. The ability to maintain a consistent flow rate also contributes to overall operational efficiency and reduces energy consumption.

Another key advantage is the versatility of screw pumps in handling various types of fluids. They are capable of transferring both viscous and non-viscous fluids, including those with high solid content. This versatility makes them suitable for diverse applications, from handling crude oil and chemical mixtures in the petrochemical industry to managing slurry and sludge in mining and sewage treatment. The ability to handle different types of fluids with minimal adjustments or modifications adds to the flexibility of screw pumps.

Screw pumps are also known for their reliability and durability. Their robust design and construction allow them to operate effectively under harsh conditions, including high pressures, temperatures, and abrasive environments. This reliability is crucial for maintaining continuous operations and minimizing downtime in industries such as steel manufacturing and coal mining. The durable materials used in screw pumps ensure a long service life and reduce the need for frequent replacements or repairs.

Low maintenance requirements are another advantage of screw pumps. Their simple design and fewer moving parts result in reduced wear and tear, leading to lower maintenance needs compared to other types of pumps. This ease of maintenance contributes to lower operational costs and increased uptime, making screw pumps a cost-effective choice for industrial applications. Regular maintenance and inspections further enhance their performance and longevity, ensuring reliable operation over time.

3.Key Considerations for Choosing Industrial Screw Pumps

Fluid Characteristics:

The type of fluid being pumped is a critical factor in choosing a screw pump. Considerations include the fluid’s viscosity, temperature, and presence of solids or abrasives. For example, in applications involving high-viscosity fluids or slurries, a screw pump designed to handle such materials is essential. Similarly, for fluids with extreme temperatures or corrosive properties, selecting a pump with appropriate materials and construction is crucial to ensure durability and reliability.

Flow Rate and Pressure Requirements:

Determining the required flow rate and pressure for the application is essential in selecting a screw pump. The pump must be capable of delivering the necessary flow rate while maintaining the required pressure. Overestimating or underestimating these requirements can lead to inefficient performance or system failures. Consulting with pump manufacturers and reviewing product specifications can help ensure that the selected pump meets the application’s needs.

Installation and Maintenance Considerations:

The ease of installation and maintenance of the pump should also be taken into account. Consider factors such as space availability, accessibility for maintenance, and the complexity of the installation process. Pumps that offer straightforward installation and low maintenance requirements can reduce operational downtime and associated costs. Additionally, selecting a pump with accessible service points and support from the manufacturer can further facilitate maintenance and repairs.

Material Compatibility:

Material compatibility is crucial for ensuring the longevity and reliability of the pump. The materials used in the pump’s construction should be compatible with the fluids being pumped to prevent corrosion, erosion, or other forms of damage. For applications involving aggressive or corrosive fluids, pumps made from specialized materials or coatings may be required to ensure optimal performance and durability.

English

English русский

русский عربى

عربى

ENG

ENG

TOP

TOP