How does Alumina Lined Ceramic Wear-Resistant Elbow ensure its wear resistance?

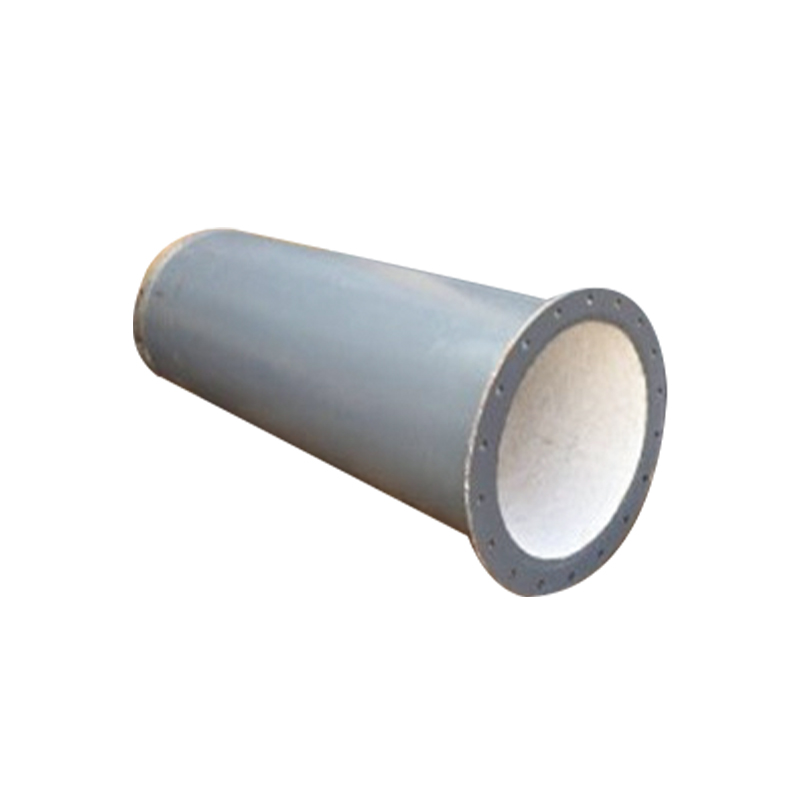

Alumina Lined Ceramic Wear-Resistant Elbow is one of the most popular components in industrial piping systems. This kind of wear-resistant ceramic elbow not only performs well in terms of wear resistance and corrosion resistance, but its unique design and manufacturing process make it particularly outstanding in harsh working conditions. The core of this product lies in its precise structural design and high-quality material selection, which is exactly the direction that Beloni (Jiangsu) Pump Manufacturing Co., Ltd. has been pursuing for many years.

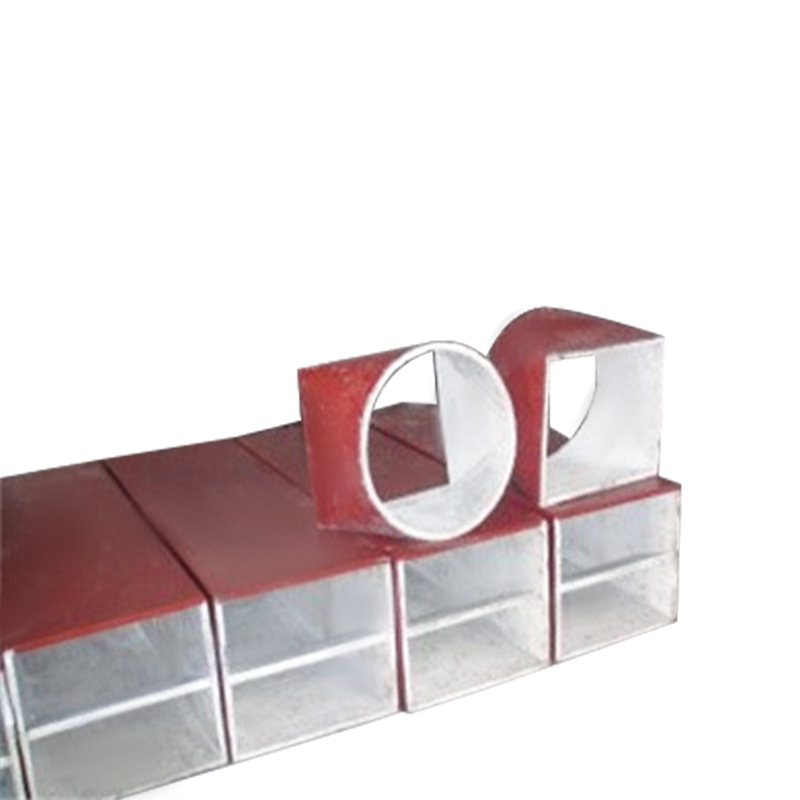

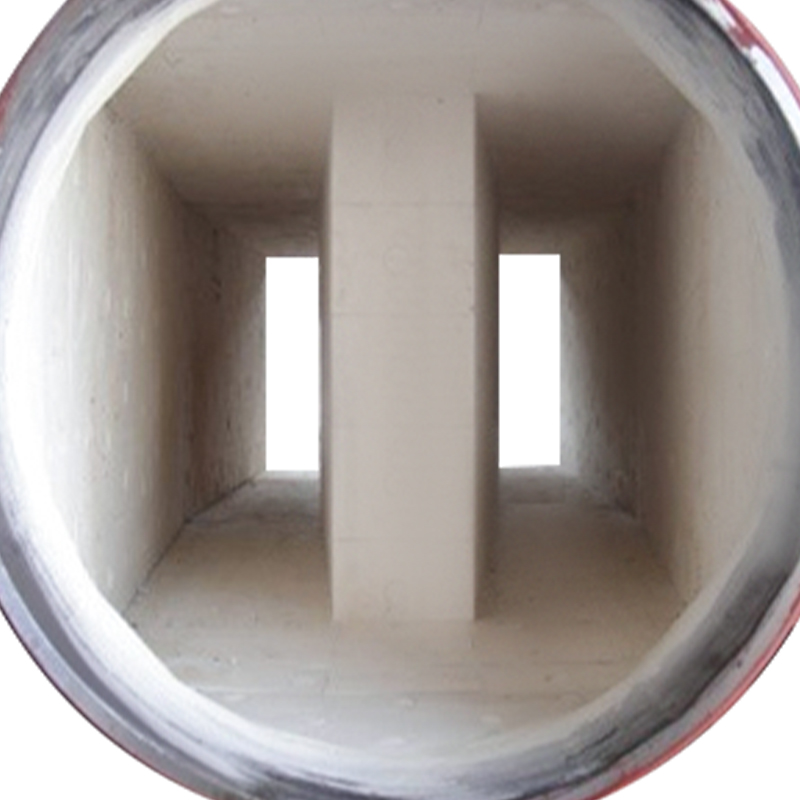

This product adopts an innovative arched self-embedding design principle, allowing the ceramic block to form a 360° mechanical self-supporting structure. The ceramic blocks are in close contact with the inner wall of the steel pipe, and the ceramic blocks are pressed against each other. This structure effectively prevents the ceramic blocks from falling off under high pressure and high impact. In addition, the gap between the ceramic block and the inner wall of the steel pipe is filled with high-temperature bonding fire clay. This dual protection mechanism significantly improves the durability of the product, allowing it to maintain long-term performance in harsh industrial environments.

Welding alumina ceramic technology is an important process breakthrough for Beloni (Jiangsu) Pump Manufacturing Co., Ltd. In this product, the ceramic block and the steel plate are combined through a dual structure of welding and bonding. This design not only greatly enhances the bonding force, but also ensures that the ceramic block will not fall off under extreme working conditions. Compared with traditional processes, this structure can better cope with the challenges of high wear and highly corrosive media, providing more reliable protection for industrial pipeline systems.

It is worth mentioning that Beloni (Jiangsu) Pump Manufacturing Co., Ltd. uses high-precision ceramic block cutting technology in the manufacturing process. Parameters such as width, edge taper and contact angle of each ceramic block are designed in CAD and precisely cut with fine steel stone cutting blades. This highly precise process ensures a tight fit between the ceramic block and the inner wall of the steel pipe, thereby reducing resistance and wear when materials flow within the pipe and improving the overall efficiency and service life of the system.

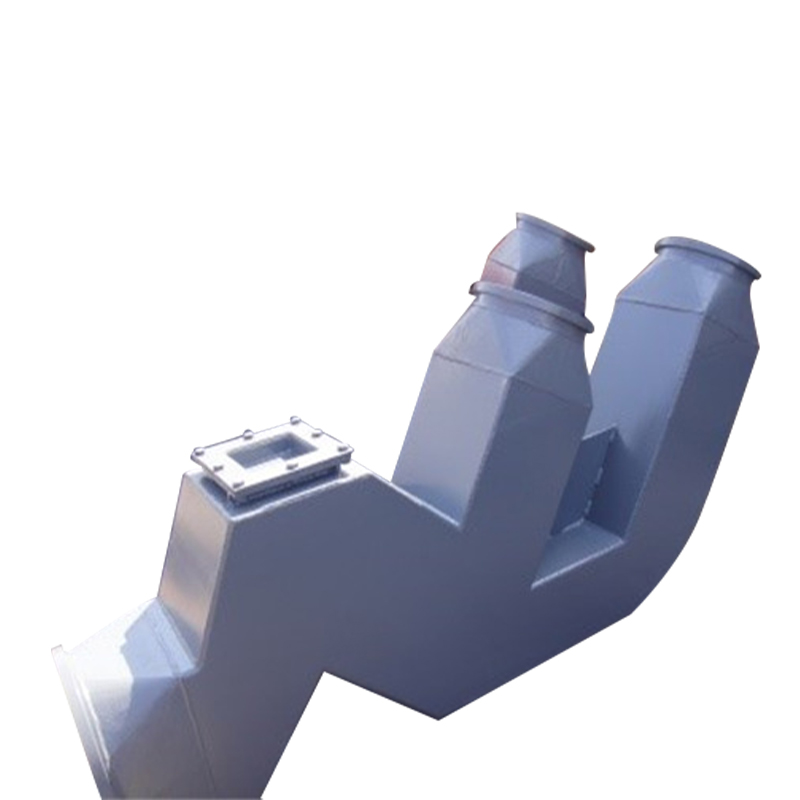

In addition to its structural and technological advantages, this wear-resistant ceramic elbow exhibits excellent performance in practical applications. Due to the use of polymer adhesive as a fixing method between the ceramic block and the steel pipe, the product can maintain stability in high temperature, high pressure and strong impact environments, showing excellent heat resistance and wear resistance. This excellent performance makes Alumina Lined Ceramic Wear-Resistant Elbow an indispensable and important component in the industrial field, especially suitable for material conveying systems in the power, mining, chemical and metallurgical industries.

By combining advanced materials science with precision manufacturing processes, Beloni (Jiangsu) Pump Manufacturing Co., Ltd. provides an efficient, reliable and durable industrial piping solution to the global market. This product not only excels in wear resistance, corrosion resistance and high temperature resistance, but also reaches high industry standards in structural design and manufacturing accuracy. Although Beloni has extensive experience in pump manufacturing, its relentless pursuit of technological innovation and product quality can still be seen in products like the Alumina Lined Ceramic Wear-Resistant Elbow. Through continuous R&D and process improvement, Beloni (Jiangsu) Pump Manufacturing Co., Ltd. will continue to provide better products and services to customers around the world, helping customers in various industries maintain efficient production and competitive advantages in the most demanding environments.

English

English русский

русский عربى

عربى

ENG

ENG

TOP

TOP