1. Introduction to Rubber Lined Pipe

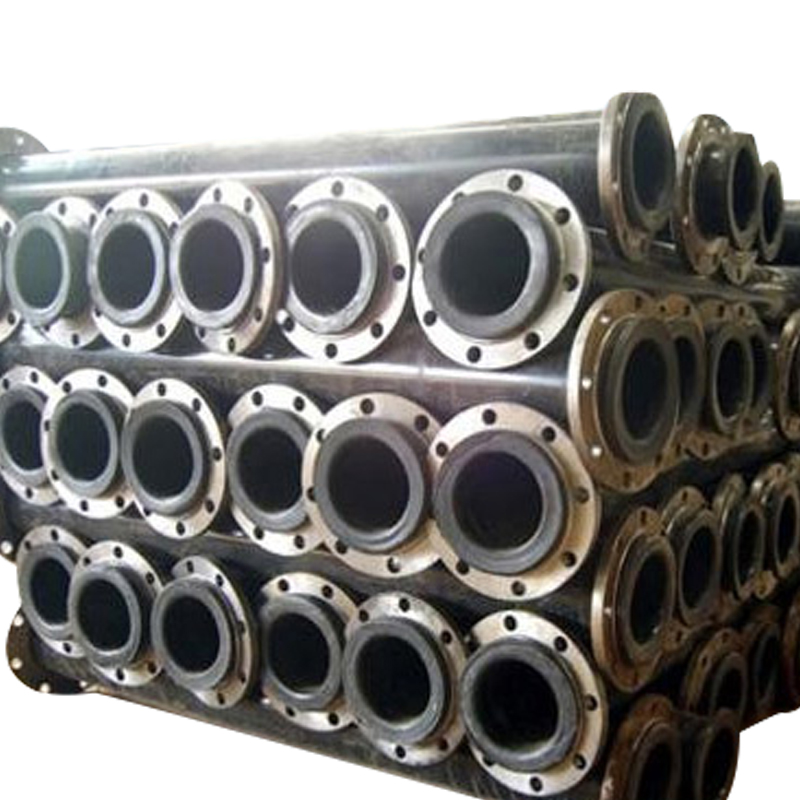

Rubber lined pipe, a specialized product engineered by Beloni (Jiangsu) Pump Manufacturing Co., Ltd., represents a significant advancement in fluid handling technology. This innovative piping system consists of a metal pipe with an inner layer of rubber meticulously applied to its internal surface. This unique construction imparts a multitude of advantages that render rubber lined pipe an indispensable component in numerous industrial applications. At the core of rubber lined pipe’s appeal lies its exceptional corrosion resistance. The rubber lining acts as a protective barrier, safeguarding the underlying metal pipe from the deleterious effects of corrosive substances. This is particularly crucial in industries that handle aggressive chemicals, where traditional metal pipes would rapidly deteriorate. By mitigating corrosion, rubber lined pipe extends the service life of the piping system, reduces maintenance costs, and ensures uninterrupted operations. Beyond corrosion resistance, rubber lined pipe exhibits remarkable abrasion resistance. The rubber lining's inherent toughness effectively protects the pipe from the erosive impact of abrasive particles carried within the fluid. This characteristic is invaluable in applications involving slurries, suspensions, and other media containing solid particulates. By minimizing abrasive wear, rubber lined pipe maintains optimal flow conditions and prevents blockages or reductions in pipe diameter. Another key benefit of rubber lined pipe is its sound attenuation properties. Rubber, as a material, possesses excellent vibration damping capabilities. Consequently, rubber lined pipe effectively reduces noise levels generated by fluid flow, creating a quieter working environment for operators and nearby personnel. This is particularly advantageous in industrial settings where noise pollution is a concern. In addition to its functional advantages, rubber lined pipe offers flexibility and ease of installation. Compared to rigid metal pipes, rubber lined pipe can be more readily manipulated and accommodated to fit various piping configurations. This flexibility simplifies the installation process, reduces labor costs, and minimizes disruptions to operations. The smooth inner surface of rubber lined pipe contributes to reduced friction and pressure drop. This translates into improved fluid flow efficiency, resulting in energy savings and increased system productivity. The combination of corrosion resistance, abrasion resistance, noise reduction, flexibility, and enhanced flow efficiency makes rubber lined pipe a compelling choice for a wide range of industries. Beloni (Jiangsu) Pump Manufacturing Co., Ltd., as a leading China Rubber Lined Pipe Manufacturers and Rubber Lined Pipe Suppliers, is committed to delivering high-quality rubber lined pipe solutions that meet the stringent demands of modern industrial processes. Through meticulous engineering, rigorous quality control, and a deep understanding of customer needs, Beloni provides rubber lined pipes that excel in performance and durability.

2. Rubber Lined Pipe Installation and Maintenance

Proper installation and maintenance are paramount to maximizing the lifespan and performance of rubber lined pipe systems. Beloni (Jiangsu) Pump Manufacturing Co., Ltd., a leading China Rubber Lined Pipe Manufacturers and Rubber Lined Pipe Suppliers, offers comprehensive support and guidance to ensure successful implementation and optimal operation.

Installation of Rubber Lined Pipe: The installation of rubber lined pipe requires careful planning and execution to guarantee its integrity and functionality. Key considerations include: Site Preparation: The installation area should be clean and free from debris, contaminants, or sharp objects that could damage the rubber lining. Proper drainage should also be established to prevent water accumulation. Pipe Handling: Exercise caution when handling rubber lined pipes to avoid damage to the lining. Use appropriate lifting equipment and avoid dragging or dropping the pipes. Cutting and Joining: If necessary, cutting and joining of rubber lined pipes should be performed by qualified personnel using specialized tools and techniques to maintain the integrity of the lining. Flange Alignment: Proper alignment of flanges is crucial to prevent stress on the rubber lining. Use appropriate gaskets and torque wrenches to ensure secure connections. Support Structures: Adequate support structures should be installed to prevent pipe sagging or excessive stress on the rubber lining. Testing and Commissioning: Upon completion of the installation, the pipe system should undergo thorough testing and commissioning to verify its performance and identify any potential issues. Beloni (Jiangsu) Pump Manufacturing Co., Ltd., provides detailed installation guidelines and technical support to assist customers in ensuring a successful installation process.

Maintenance of Rubber Lined Pipe: Regular inspection and maintenance are essential for prolonging the life of rubber lined pipe and preventing unexpected failures. Key maintenance practices include: Visual Inspection: Conduct regular visual inspections of the pipe system to identify any signs of damage, wear, or deterioration of the rubber lining. Look for cracks, blisters, abrasions, or other abnormalities. Pressure Monitoring: Monitor operating pressures to ensure they remain within the recommended limits. Excessive pressure can cause damage to the rubber lining. Temperature Monitoring: Monitor fluid temperatures to prevent overheating, which can degrade the rubber lining. Chemical Compatibility: Regularly assess the compatibility of the fluid being transported with the rubber lining material. Avoid exposure to incompatible chemicals. Cleaning and Flushing: Periodically clean the pipe system to remove deposits and prevent buildup, which can damage the lining. Use appropriate cleaning agents that are compatible with the rubber lining. Repairs: If any damage to the rubber lining is detected, promptly initiate repairs to prevent further deterioration. Contact Beloni for guidance on repair procedures and materials.

Common Issues and Troubleshooting: Despite careful installation and maintenance, issues may arise with rubber lined pipe systems. Some common problems and potential solutions include: Rubber Lining Damage: If the rubber lining is damaged, it may be necessary to repair or replace the affected section of the pipe. Corrosion: While rubber lined pipe offers excellent corrosion resistance, it is essential to monitor for any signs of corrosion on the underlying metal pipe. If corrosion is detected, it may be necessary to replace the pipe. Abrasion: Excessive abrasion can lead to premature wear of the rubber lining. Consider using more abrasion-resistant rubber compounds or implementing measures to reduce abrasive particles in the fluid. Leaks: Leaks can occur at pipe joints or due to damage to the rubber lining. Proper tightening of flanges and prompt repair of any damage can help prevent leaks. Beloni (Jiangsu) Pump Manufacturing Co., Ltd., offers comprehensive troubleshooting support to assist customers in addressing any issues that may arise with their rubber lined pipe systems.

English

English русский

русский عربى

عربى

ENG

ENG

TOP

TOP