The process of preheating and reduction in the metallurgical process of Blast Furnace

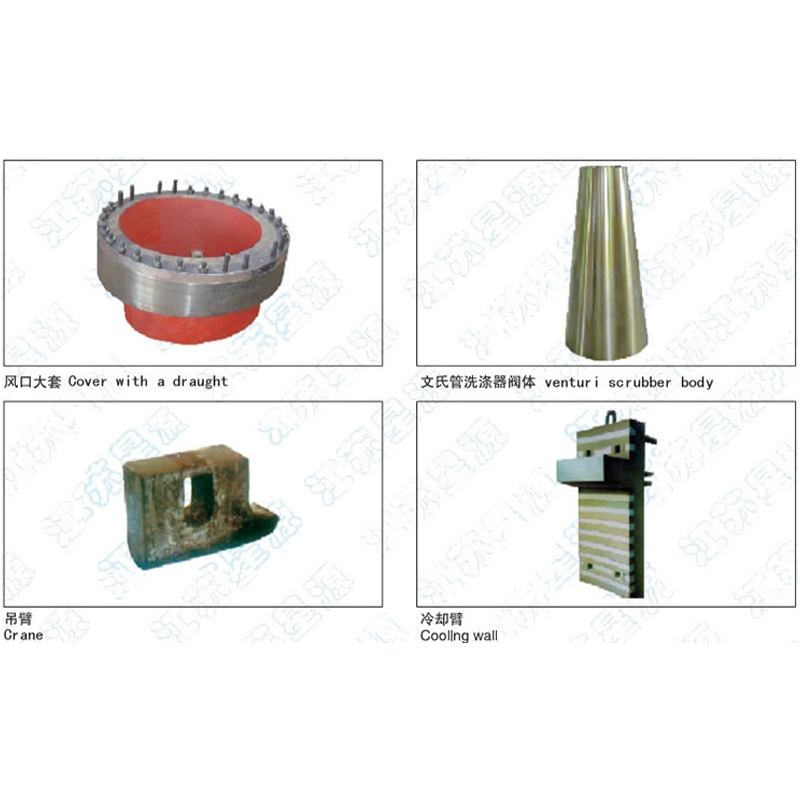

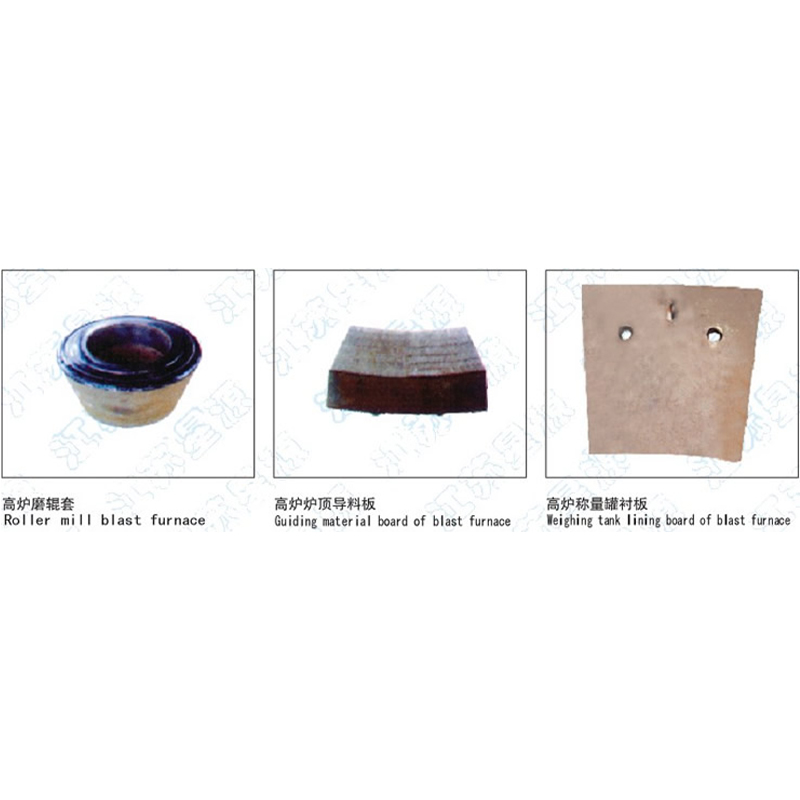

Beloni (Jiangsu) Pump Manufacturing Co., Ltd. is a technology-based manufacturer integrating chemical pump design, R&D, manufacturing, sales and service. Its product line is extensive and in-depth, covering multiple series such as magnetic pumps, axial flow pumps, horizontal self-priming pumps, fluorine-lined centrifugal pumps, and chemical desulfurization pumps. Each series has been carefully designed and rigorously tested to ensure that it can show excellent performance under different working conditions. Beloni (Jiangsu) Pump Manufacturing Co., Ltd. also focuses on the research and development and production of metallurgical equipment, such as rare earth heat-resistant steel series, rare earth wear-resistant alloy steel series, and walking beam heating furnaces. The high-quality and high-efficiency characteristics of the products meet the customer's demand for high-end metallurgical equipment. The following will focus on technology and deeply analyze the crucial preheating and reduction stages in the metallurgical process of Blast Furnace, revealing how this complex and delicate process can be carried out efficiently and stably with the support of our high-quality pump products and metallurgical equipment.

The blast furnace is the "heart" of the steel industry. The chemical reactions and physical changes inside it are the core of steel production. Preheating and reduction are the first two key steps in blast furnace metallurgy, which directly determine the subsequent molten iron output and quality. At this stage, raw materials such as iron ore and coke undergo a gorgeous transformation from solid to liquid under the action of high temperature and reducing gas, and finally precipitate pure molten iron.

1. Preheating is the first step in blast furnace smelting and the basis for providing necessary heat for subsequent reduction reactions. Beloni (Jiangsu) Pump Manufacturing Co., Ltd. pays special attention to the design and optimization of the blast furnace preheating system to ensure that the raw materials can fully absorb heat before entering the blast furnace and improve the overall smelting efficiency.

Some technical highlights are as follows.

Efficient hot air system: Beloni (Jiangsu) Pump Manufacturing Co., Ltd. has equipped the blast furnace with an advanced hot air furnace system. By optimizing the combustion process and heat exchange efficiency, the preheated air is heated to an extremely high temperature and then sent into the blast furnace. These high-temperature hot blasts provide the necessary heat for the inside of the blast furnace and also promote the combustion of coke and the generation of reducing gases.

Raw material preheating device: Before the raw materials enter the blast furnace, advanced preheating devices are used to preheat the iron ore and coke. These devices use the waste heat in the blast furnace exhaust gas to heat the raw materials, increase the temperature of the raw materials entering the furnace, and realize the recycling of energy.

2. Reduction is the core step of blast furnace smelting and the key process for the conversion of iron oxides in iron ore into metallic iron. At this stage, reducing gases such as carbon monoxide produced by the combustion of coke combine with oxygen in the iron ore to reduce iron oxides to metallic iron. Beloni (Jiangsu) Pump Manufacturing Co., Ltd.'s deep accumulation in the field of metallurgical equipment provides strong technical support for blast furnace reduction reactions.

The specific technical details are as follows.

Precisely control air temperature and air volume: The efficiency of blast furnace reduction reaction is closely related to parameters such as air temperature and air volume. Beloni (Jiangsu) Pump Manufacturing Co., Ltd. adopts advanced automatic control system to adjust air temperature and air volume in real time according to the operation status of blast furnace to ensure that the reduction reaction is carried out under the best conditions. At the same time, our pump products play a key role in the blast furnace air supply system, ensuring the stable delivery and precise regulation of hot air.

Optimize the charge structure: The impact of the charge structure on the blast furnace reduction reaction cannot be ignored. Beloni (Jiangsu) Pump Manufacturing Co., Ltd. tailors the charge structure plan for customers according to factors such as iron ore type, coke quality and blast furnace operating conditions. Through reasonable batching ratio and distribution method, the air permeability and reduction efficiency of the blast furnace are improved.

Strengthen the reaction kinetics in the furnace: In order to further improve the reduction reaction rate and efficiency, Beloni (Jiangsu) Pump Manufacturing Co., Ltd. is committed to studying the optimization strategy of the reaction kinetics in the furnace. By improving the lining materials of t

he blast furnace, optimizing the furnace structure and introducing advanced catalysts, we have effectively reduced the activation energy of the reduction reaction and accelerated the reduction process of iron oxides.

3. While pursuing efficient smelting, Beloni (Jiangsu) Pump Manufacturing Co., Ltd. has always regarded environmental protection and energy efficiency as the core values of corporate development. A large amount of waste gas, waste slag and other pollutants will be generated during the blast furnace smelting process. Therefore, we have fully considered environmental protection factors in the equipment design and manufacturing process.

Waste gas treatment technology: Beloni (Jiangsu) Pump Manufacturing Co., Ltd. has equipped the blast furnace with an efficient waste gas treatment system, which treats harmful substances in the blast furnace waste gas through processes such as desulfurization and denitrification to ensure that the waste gas emissions meet national environmental protection standards.

Waste heat recovery technology: In order to improve energy utilization efficiency, Beloni (Jiangsu) Pump Manufacturing Co., Ltd. uses advanced waste heat recovery technology to recycle and reuse the waste heat in the blast furnace waste gas. This waste heat can be used to preheat raw materials and hot air systems, and can also be used for heating needs in other production links.

English

English русский

русский عربى

عربى

ENG

ENG

TOP

TOP