What is the specific process of Pipeline (Expansion Joint) Compensator compensation displacement?

Beloni (Jiangsu) Pump Manufacturing Co., Ltd. is located in Jingjiang City, a city with beautiful scenery and convenient transportation on the lower reaches of the Yangtze River. It is a technology-based enterprise deeply engaged in the field of pump products and metallurgical equipment. Since its establishment, Beloni (Jiangsu) Pump Manufacturing Co., Ltd. has always adhered to the business philosophy of "quality-oriented, innovation-first", and is committed to providing comprehensive, efficient and safe industrial fluid transportation solutions for the global and domestic markets. Pipeline (Expansion Joint) Compensator is one of our products. The following will explore the specific process of Pipeline (Expansion Joint) Compensator compensation displacement and show the technical essence behind it.

In the pipeline system, due to changes in medium temperature, pressure fluctuations and the thermal expansion and contraction characteristics of the pipeline itself, the pipeline will inevitably undergo axial, lateral or angular displacement. If these displacements are not effectively compensated and controlled, it will cause excessive stress concentration in the pipeline system, which will lead to serious consequences such as pipeline rupture and leakage. Pipeline (Expansion Joint) Compensator came into being, and its elastic deformation ability became the key to solving this problem.

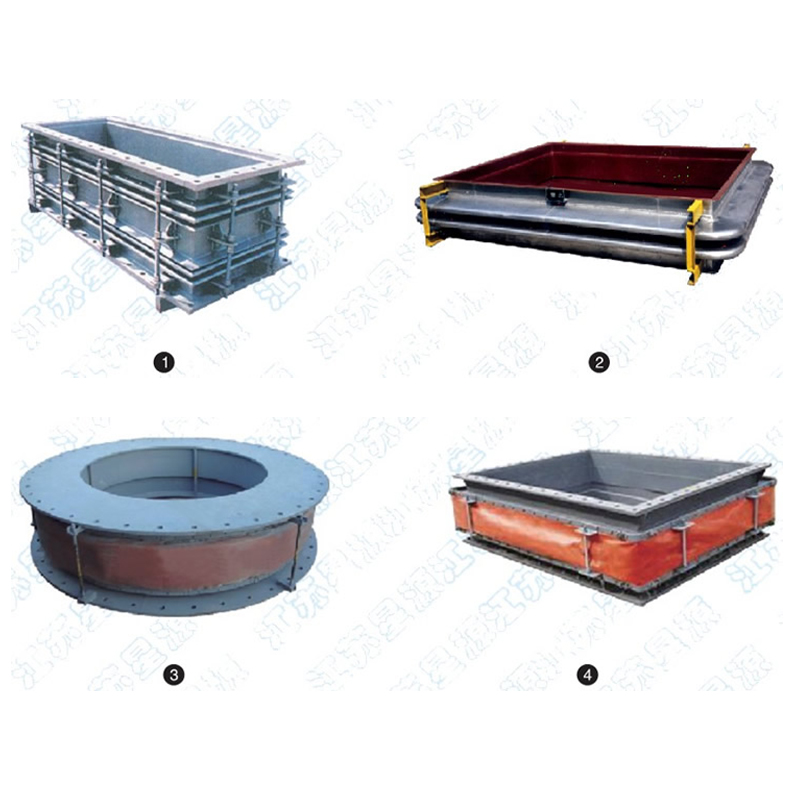

1. The Pipeline (Expansion Joint) Compensator of Beloni (Jiangsu) Pump Manufacturing Co., Ltd. usually uses bellows as the main elastic element, supplemented by flanges, pipes, guide devices and sealing structures. The bellows is the heart of the compensator. Its unique wave structure gives it good expansion and contraction deformation ability. When the pipeline system is displaced, the bellows will correspondingly expand and contract in the axial, lateral or angular directions, thereby absorbing and compensating these displacements.

2. Specific process of compensation displacement

Initial state and displacement generation: Before the normal operation of the pipeline system, the Pipeline (Expansion Joint) Compensator is in the initial state. At this time, the bellows is in a natural state without any deformation. As the pipeline system starts to operate, the pipeline begins to displace due to factors such as temperature changes and medium flow. These displacements may be axial (along the length of the pipe), transverse (perpendicular to the length of the pipe) or angular (pipe axis deflection).

Elastic deformation of bellows: When the pipe is displaced, the bellows in the connected Pipeline (Expansion Joint) Compensator begin to play a role. Depending on the direction and size of the displacement, the bellows will elastically deform accordingly. For axial displacement, the bellows will expand and contract along the length of the pipe; for lateral displacement, the bellows will absorb it through the bending deformation of its wave structure; and angular displacement will cause the bellows to twist or bend in combination.

Synergy of guide device and sealing structure: While the bellows are elastically deforming, the guide device and sealing structure in the Pipeline (Expansion Joint) Compensator also play an important role. The guide device is used to limit the deformation direction of the bellows, prevent it from unexpected twisting or buckling, and protect the bellows from damage. The sealing structure ensures that the sealing of the pipeline system is not affected during the deformation of the bellows to prevent medium leakage.

Transmission and absorption of displacement: As the bellows continues to deform, the displacement in the pipeline system is gradually transmitted and absorbed into the Pipeline (Expansion Joint) Compensator. This process is continuous and dynamic, ensuring that the pipeline system can maintain a stable operating state under different working conditions. Since the bellows has good elastic recovery ability, it can quickly return to its initial state after the displacement disappears, ready for the next displacement compensation.

Some of the technical features and advantages of the Pipeline (Expansion Joint) Compensator of Beloni (Jiangsu) Pump Manufacturing Co., Ltd. in compensating displacement are as follows.

High precision: Through precise design and manufacturing processes, the bellows are ensured to have precise deformation ability and stability, and can accurately compensate for the displacement of the pipeline system.

High reliability: The use of high-quality materials and advanced production processes ensures that the compensator can still operate stably for a long time under harsh working conditions and reduce the failure rate.

Multi-directional compensation: It can simultaneously compensate for axial, lateral and angular displacements to meet the needs of complex pipeline systems.

Easy installatio

n and maintenance: The structural design is reasonable, and the installation is simple and quick; at the same time, the design of the sealing structure and the guide device is also convenient for daily maintenance and repair.

Beloni (Jiangsu) Pump Manufacturing Co., Ltd. relies on its deep accumulation and technological innovation in the field of chemical pumps and metallurgical equipment to provide customers with high-quality and high-performance Pipeline (Expansion Joint) Compensator solutions. Through continuous technical research and development and product optimization, it hopes to better serve customers and jointly promote the technological progress and development of industrial pipeline systems.

English

English русский

русский عربى

عربى

ENG

ENG

TOP

TOP