What is the new sealing technology of Radiant Tube?

Beloni (Jiangsu) Pump Manufacturing Co., Ltd. has excellent performance products and a perfect service system, which are widely used in many industries such as petrochemical, coal mines, power plants, steel mills, agricultural irrigation and drainage, industrial water supply and drainage, municipal construction, sewage treatment, etc. Beloni (Jiangsu) Pump Manufacturing Co., Ltd. is constantly improving its system service capabilities and providing customers with one-stop services from pre-sales consultation, solution design to after-sales maintenance. Below we will explore the new sealing technology of Radiant Tube in depth. The birth of this technology marks another major breakthrough in the field of heat exchange equipment.

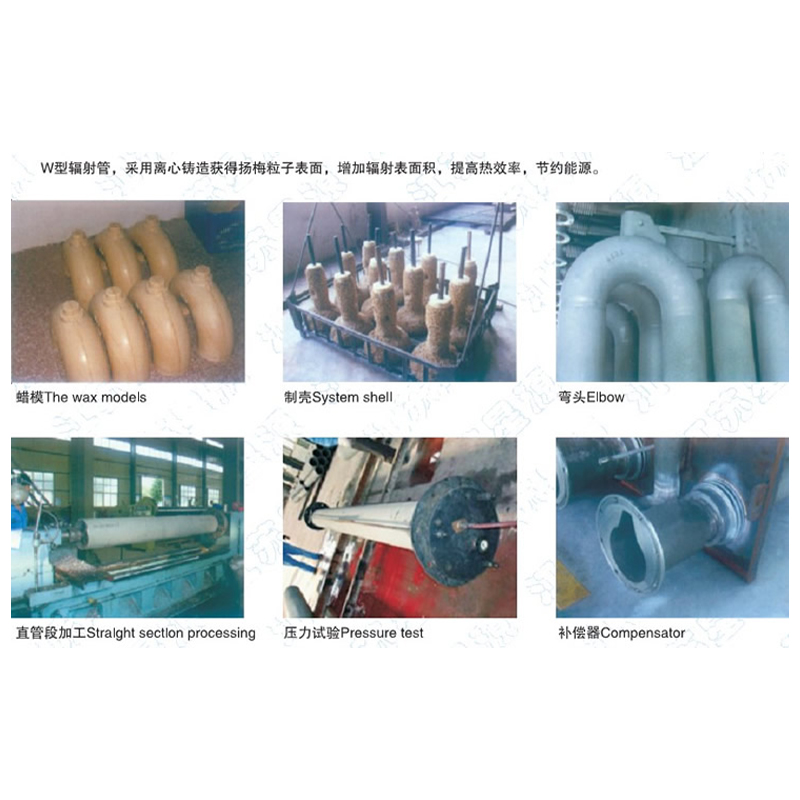

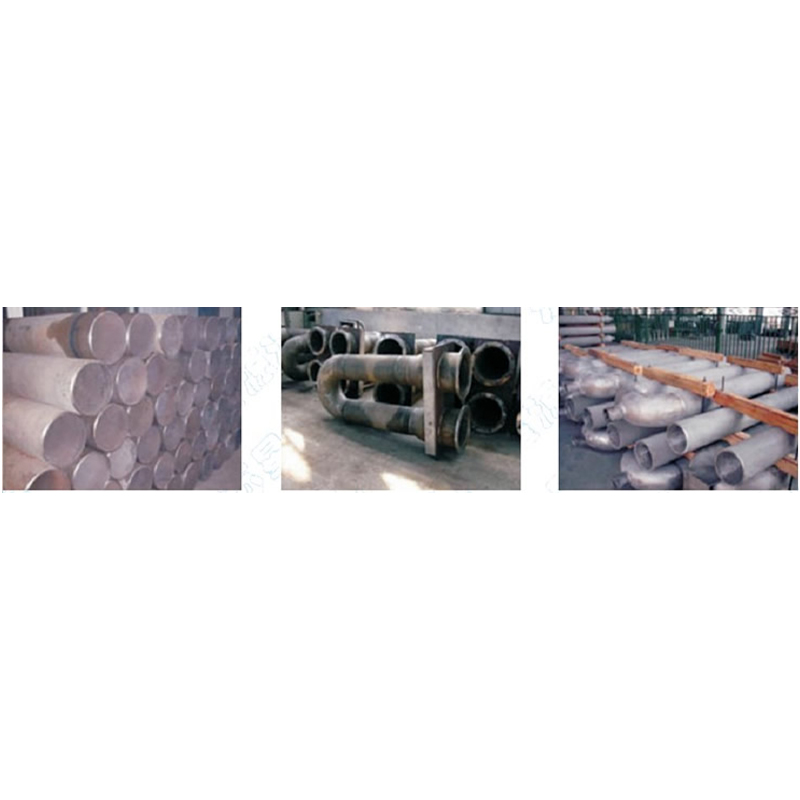

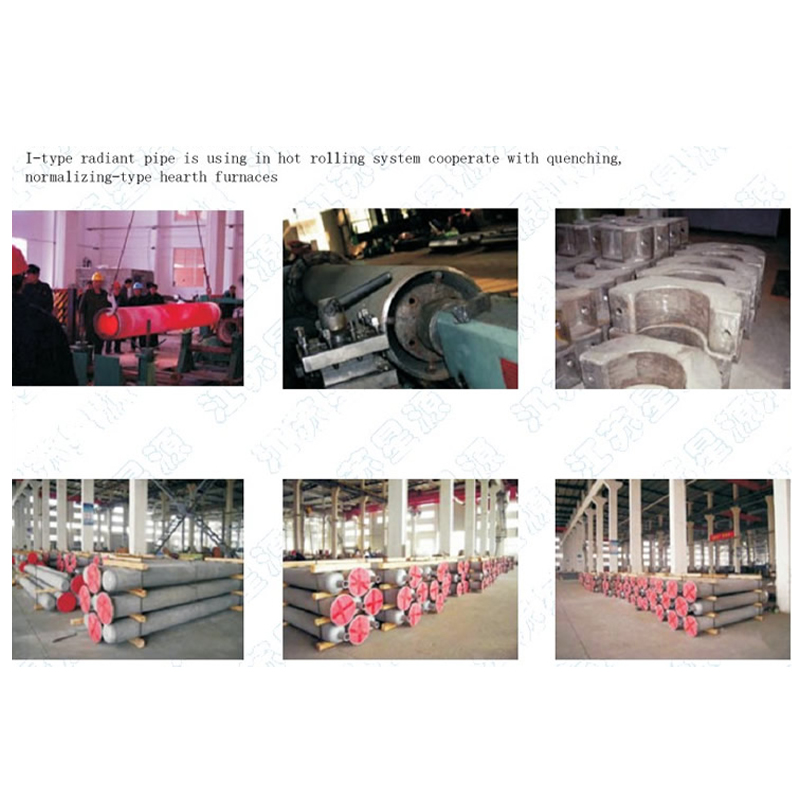

Radiant Tube is one of the heat exchange equipment, which is widely used in many industries such as metallurgy, steel, chemical industry, and electric power. It has a unique radiation heating method, which realizes efficient heat transfer and uniform distribution, and has become an indispensable key equipment in high temperature environment. With the continuous advancement of industrial technology and the increasing complexity of application scenarios, traditional sealing technology often seems to be unable to cope with extreme working conditions such as high temperature, high pressure, and corrosive media.

1. Technical highlights and innovations

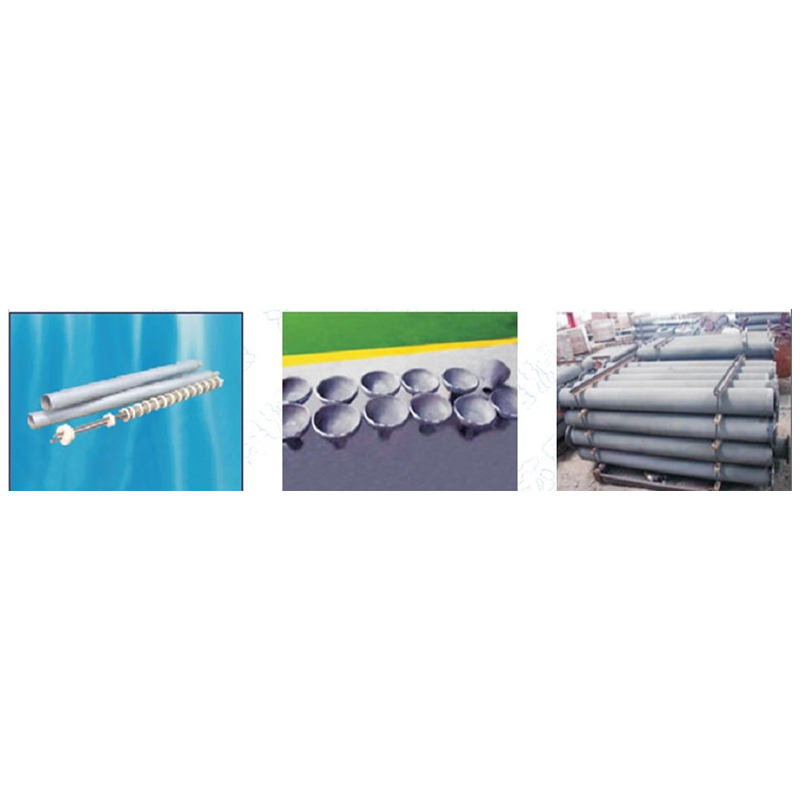

Application of high-temperature resistant materials: The core of the new sealing technology is that it uses advanced high-temperature resistant materials. These materials are processed by special processes and can maintain stable physical and chemical properties in extremely high temperature environments. They also have excellent corrosion resistance and wear resistance. Even under working conditions of up to thousands of degrees Celsius, the sealing components can maintain a good sealing effect and effectively prevent the leakage of heat and media.

Multiple sealing structure design: In order to further improve the sealing performance, Beloni (Jiangsu) Pump Manufacturing Co., Ltd. adopts a multiple sealing structure design. This design forms a solid barrier through the superposition and interaction of multiple layers of sealing elements, effectively blocking the leakage of media and heat. The multiple sealing structure also has a self-compensation function, which can automatically adjust the sealing gap during the operation of the equipment to ensure a long-term stable sealing effect.

Intelligent monitoring and early warning system: In addition to hardware innovations, Beloni (Jiangsu) Pump Manufacturing Co., Ltd. has also introduced an intelligent monitoring and early warning system, which realizes real-time monitoring and early warning of the sealing performance of Radiant Tube by integrating sensors, data analysis algorithms and cloud computing technologies. Once any abnormality is detected, the system will immediately sound an alarm and provide detailed fault information and solutions to help users eliminate hidden dangers in time and ensure the safe operation of the equipment.

2. Application examples and effect display

Since the successful development of the new sealing technology, Beloni (Jiangsu) Pump Manufacturing Co., Ltd. has applied it to multiple industrial projects and achieved remarkable results. For example, in the continuous heating furnace project of a large steel company, the equipment using our Radiant Tube new sealing technology showed extremely high stability and reliability during operation. Compared with traditional sealing technology, the equipment significantly reduces the risk of heat loss and medium leakage, and also improves heating efficiency and product quality. Due to the reduction in the number of shutdown maintenance and replacement of sealing parts, the company's production costs are also effectively controlled.

3. Beloni (Jiangsu) Pump Manufacturing Co., Ltd. is an enterprise driven by technological innovation. It has always adhered to the business philosophy of "quality-oriented, innovation-first", and continuously increased its investment in the research and development of new technologies and new products. In the future, we will continue to deepen cooperation and exchanges with domestic and foreign scientific research institutions, universities and industry partners to jointly promote the upgrading and application expansion of Radiant Tube's new sealing technology. At the same time, we will actively explore innovative possibilities in more areas to provide more comprehensive, efficient and environmentally friendly fluid transmission solutions for global industrial users.

English

English русский

русский عربى

عربى

ENG

ENG

TOP

TOP