Hot pressing sintering technology improves material density and strength

Densification process

Principle: Hot pressing sintering densifies powder materials under high temperature and pressure, causing plastic flow and contact between powder particles, filling the gaps between particles, and forming a dense solid material. This process combines the advantages of traditional sintering and pressure processing and can significantly increase the density of the material.

Effect: The increase in density means the reduction of pores inside the material and the enhancement of the bonding force between particles, thereby significantly improving the mechanical properties of the material.

Increased strength

Microstructure: During the hot pressing sintering process, the powder particles undergo plastic deformation and diffusion connection under high temperature and pressure, forming a fine grain structure. Fine grains help inhibit the expansion of cracks and improve the strength and toughness of the material.

Physical properties: Optimization of density and grain structure allows the material to better resist damage when subjected to external forces, showing higher strength and hardness.

Application advantages of hot press sintering

Improve product quality

Pump products: Combined with the pump products of Beloni Pump Manufacturing Co., Ltd., such as wear-resistant pumps, corrosion-resistant pumps, etc., hot press sintering technology can prepare high-density, high-strength pump bodies, impellers and other key components . These components are better able to resist wear, corrosion and fatigue damage, extending the life of the pump.

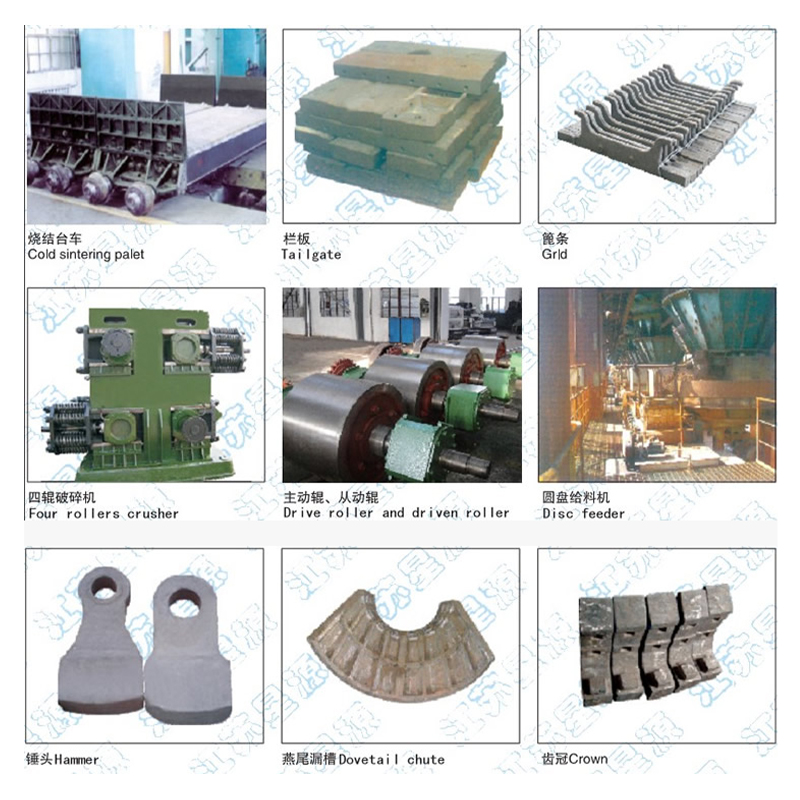

Metallurgical equipment: In metallurgical equipment, hot-press sintering technology can be used to prepare high-temperature-resistant and wear-resistant components, such as rare earth heat-resistant steel components, wear-resistant ceramic patches, etc. These components maintain good performance under harsh operating conditions.

Reduce production costs

Energy Saving: Compared with conventional sintering methods, hot-press sintering can achieve densification of materials at lower temperatures, thus saving energy and time.

Material utilization rate: Since the filling effect of powder particles is better during the hot pressing sintering process, the material utilization rate can be improved and waste generation can be reduced.

Improve production efficiency

Process optimization: Hot pressing sintering technology combines the molding and sintering processes into one step, simplifying the production process and improving production efficiency.

Automated production: Combining Beloni's resources such as advanced metal cutting equipment, computer CAD-aided design, and detection and measurement devices, automated production of the hot-pressing sintering process can be realized, further improving production efficiency and quality stability.

English

English русский

русский عربى

عربى

ENG

ENG

TOP

TOP