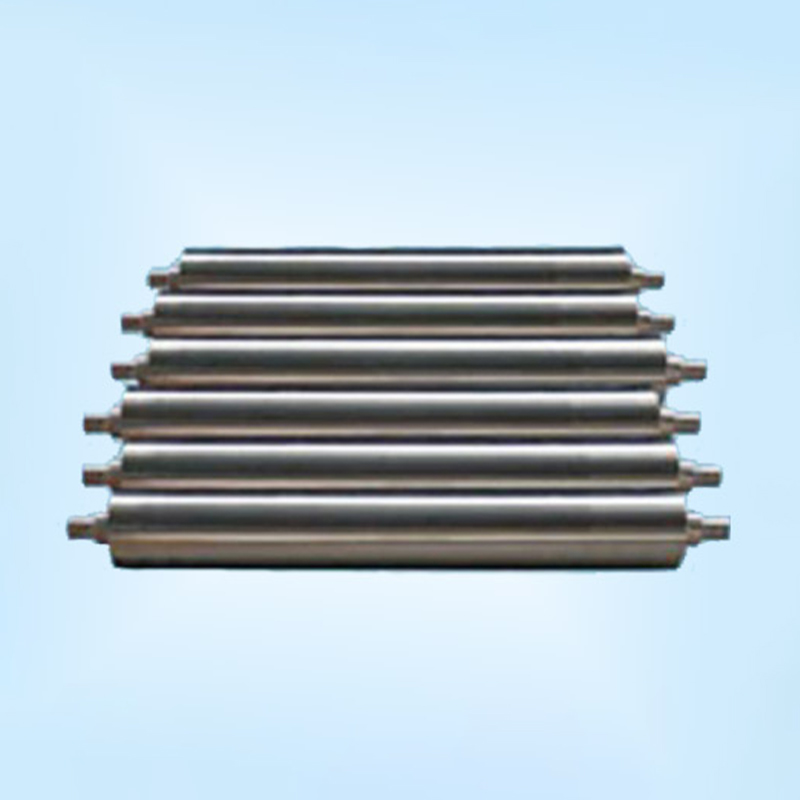

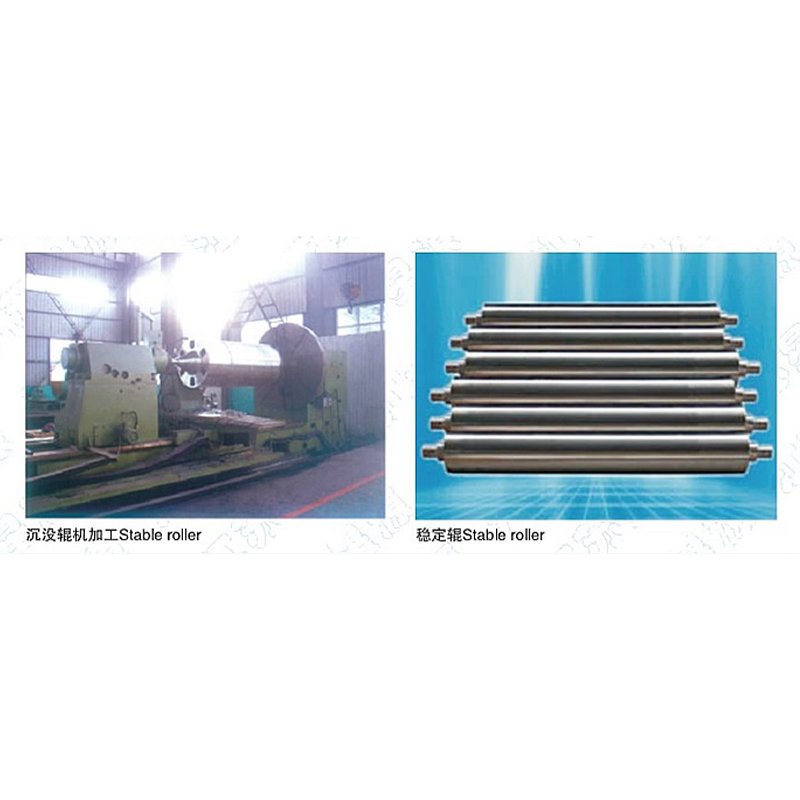

Selection of heat-resistant materials for stabilizing roller

Stabilizing rollers are mainly used to maintain the stability and continuity of production lines in the metallurgical industry. Their working environment is often accompanied by high temperatures and certain corrosive gases. Therefore, when selecting heat-resistant materials, it is necessary to focus on the high-temperature strength, corrosion resistance and thermal stability of the materials. Beloni Pump Manufacturing Co., Ltd. usually uses heat-resistant alloy steel as the main material for stabilizing rollers. This type of material not only has good high-temperature strength and corrosion resistance, but also can maintain stable performance in a high-temperature environment for a long time. In addition, Beloni will also perform appropriate heat treatment and surface strengthening treatment on the material according to specific working conditions to further improve its service life and reliability.

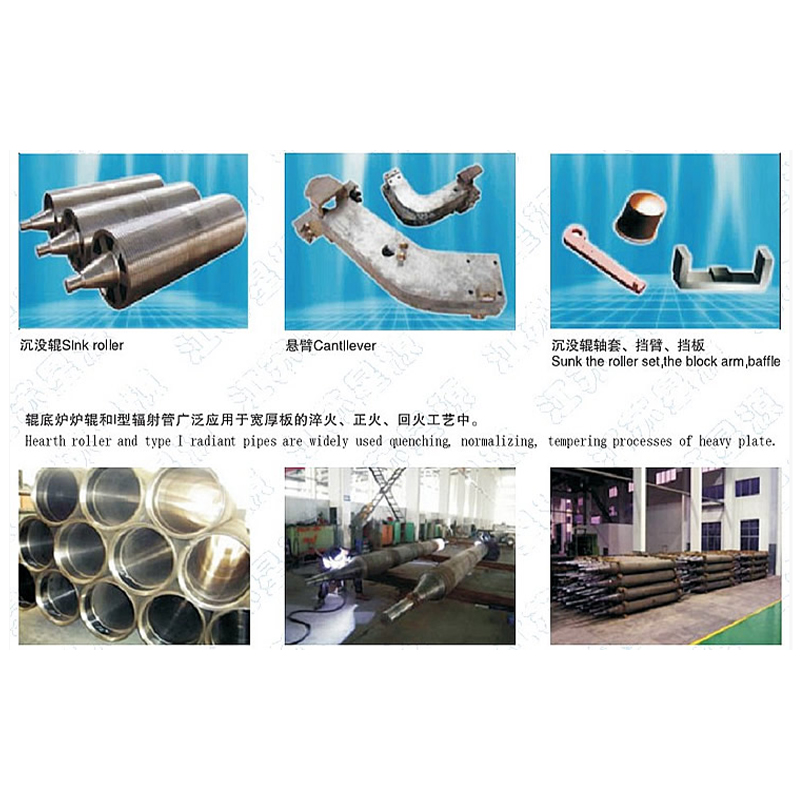

Selection of heat-resistant materials for sinking roller

The sinking roller is a key component used in continuous casting and other processes in the metallurgical industry. Its working environment is more severe and it needs to withstand extremely high temperatures and strong wear. Therefore, when selecting heat-resistant materials for sinking rollers, it is necessary to pay more attention to the wear resistance, high temperature resistance and thermal shock resistance of the materials. Beloni usually uses nickel-based alloys or cobalt-based alloys as the main materials for sinking rollers. Nickel-based alloys are known for their excellent high temperature resistance, corrosion resistance and good processing performance; while cobalt-based alloys have higher high temperature strength and wear resistance, and are suitable for extreme working conditions. In addition, the company will also specially design and customize the sinking roller according to customer needs and working conditions to meet the different needs of different customers.

Furnace roller heat-resistant material selection

Furnace rollers are core components used in heating furnaces and other equipment in the metallurgical industry. Their working environment temperature is extremely high and they need to withstand the erosion of various corrosive gases in the furnace. Therefore, when selecting heat-resistant materials for furnace rollers, factors such as high temperature strength, corrosion resistance, thermal conductivity and cost-effectiveness of the materials need to be considered comprehensively. Beloni usually uses a combination of multiple materials to manufacture furnace rollers, such as composite materials such as metal matrix combined with ceramic coatings. This composite material can not only give play to the strength and toughness advantages of metal materials, but also take advantage of the high temperature resistance, corrosion resistance and wear resistance of ceramic materials, thereby achieving complementary advantages in performance. In addition, the company will optimize the material and structure of the furnace roller according to the different furnace temperature and medium properties to ensure its long-term stable operation in high temperature environments.

English

English русский

русский عربى

عربى

ENG

ENG

TOP

TOP