Detailed explanation of the sedimentation and collection link of the water slag dust removal system

The sedimentation and collection link of the water slag dust removal system is the key part of the whole system to achieve efficient dust removal and environmentally friendly emissions. Beloni Pump Manufacturing Co., Ltd has made great efforts in the sedimentation and collection link of the water slag dust removal system.

Sedimentation principle and design optimization

In the water slag dust removal system, sedimentation refers to the process in which the particles in the dust-laden water flow gradually settle to the bottom of the system under the action of gravity after being sprayed or flushed by water mist. The design optimization of this process is directly related to the dust removal efficiency and the stable operation of the system.

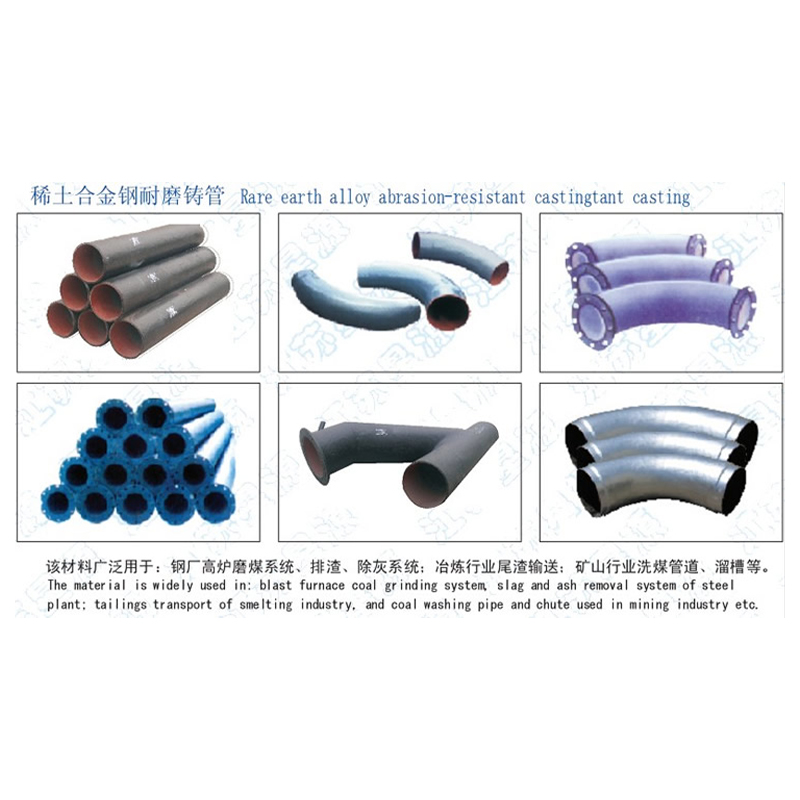

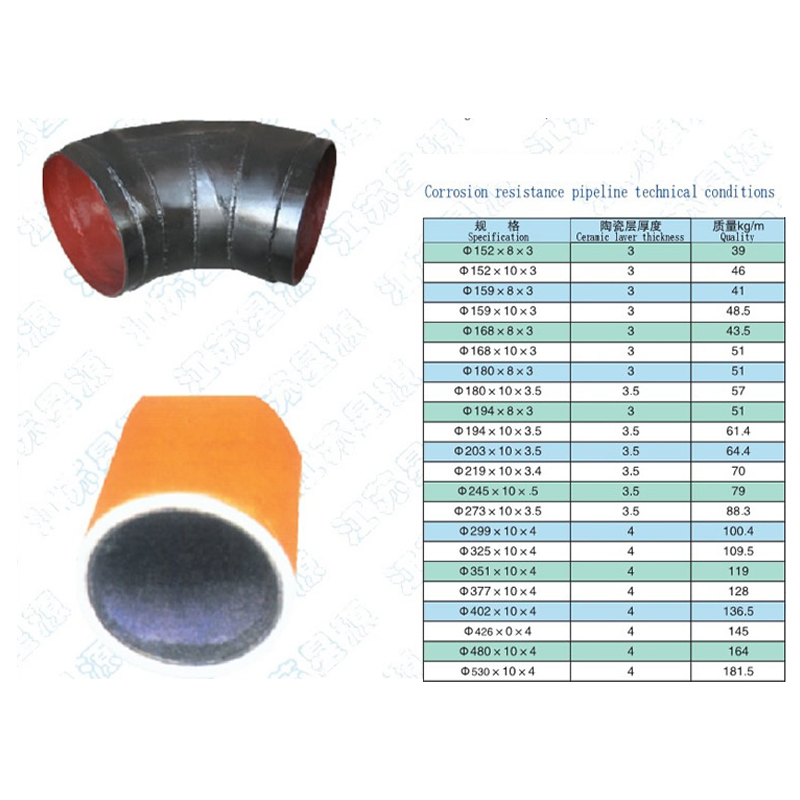

Gravity sedimentation chamber design: The system adopts an efficient gravity sedimentation chamber design, which ensures that the particles can be fully settled by reasonably controlling the structural size, flow velocity distribution and flow state of the sedimentation chamber. Wear-resistant and corrosion-resistant materials are used inside the sedimentation chamber to cope with the flushing and corrosion of dust-laden water flow.

Flow simulation and optimization: Using computer CAD-aided design technology, Beloni simulates and optimizes the flow pattern in the sedimentation chamber to ensure uniform distribution of water flow, reduce eddy currents and short-circuit phenomena, and improve sedimentation efficiency.

Collection device

The collection device is the final destination of the settled particles, and its design and operating efficiency directly affect the overall performance of the system.

Efficient collection tank: The water slag dust removal system is equipped with an efficient collection tank with large capacity and solid structure, which can accommodate a large amount of settled particles and water. There are sludge discharge ports and sewage discharge ports at the bottom of the collection tank for regular cleaning and maintenance.

Classification treatment: According to the nature and purpose of the particles, a classification treatment plan can be provided. For recyclable particles, such as metal particles, mineral particles, etc., they are separated, purified and reused; for particles that cannot be recycled, they are safely disposed of to avoid secondary pollution to the environment.

English

English русский

русский عربى

عربى

ENG

ENG

TOP

TOP